هل سبق وتساءلت عن كيفية صنع الألعاب، أو غلاف الهواتف أو أشياء بلاستيكية أخرى؟ إنه أمر مثير للاهتمام! حقن التشكيلThis هو أحد الطرق التي يتم بها تصنيع هذه المنتجات. تُعرَّف ماكينة حقن التشكيل كعملية تصنيع خاصة، والتي كانت تُستخدم في الماضي للحصول على قطع بلاستيكية بسرعة وكفاءة. أحد العوامل الرئيسية التي تجعل من الممكن إنتاج كميات كبيرة بسهولة وسرعة هو استخدام هذه الآلة.

العامل الأهم هو أنه يقلل بشكل كبير من إنتاج القطع البلاستيكية مثل ماكينة تشكيل بالحقن. أما في Formleast، فإن الخطوة الأولى هي قالب يمكنه تقليق أي شكل ثلاثي الأبعاد. هذا القالب مهم لأنه يضخ شكل المنتج. بمجرد إعداد القالب، فإنه يستخدم قطع بلاستيكية صغيرة يتم إذابتها إلى حالة سائلة على شكل حبيبات صغيرة. الإذابة ضرورية لأنها تذيب البلاستيك الصلب وتحوله إلى شكل قابل للتشكيل. بعد إذابة البلاستيك، يتم دفعه إلى القالب السائل. يفتح القالب ويُزال الجزء المكتمل من البلاستيك بمجرد أن يبرد ويتماسك. يمكن أن يحدث هذا العملية آلاف المرات في يوم واحد، مما يزيد من معدل الإنتاج ويوفّر المال للشركات.

السبب الأكثر وضوحًا لاستخدام ماكينة تشكيل بالحقن هو سرعتها العالية. تستخدم هذه الآلة من قبل الشركات المصنعة لإنتاج آلاف الأجزاء في يوم واحد. هذا أسرع بكثير مقارنة بصنعها يدويًا، مما يستغرق الكثير من الوقت. يمكن استخدام هذه الآلة لتصنيع أجزاء معقدة ذات مجموعة متنوعة من الهندسات والخصائص. يعني ذلك أنها قادرة على إنتاج ألعاب ذات تفاصيل دقيقة أو غطاء هاتف يمكنه أن يتناسب مع الجهاز بشكل صحيح. كما أن هذه الآلة توفر اتساقًا في المنتج، حيث يكون كل جزء مصنوع بنفس الحجم تمامًا. تعريف البناء بطريقة متسقة يجعل الكود أسهل في التنظيم والتعامل، حيث يتوقع العملاء أن تظهر منتجاتهم وتتصرف كما هو متوقع في النهاية.

لهذا السبب يظل مكبس تشكيل بالحقن خيارًا مفضلًا بين المصنعين لإنتاج قطع ذات جودة عالية ومتساوية. كل شيء آخر يتعلق بطرق تصنيع الأشياء باستخدام قالب، مما يضمن أن القطع تم إعدادها بدقة كبيرة. وبالتالي، يتم تصنيع كل قطعة بنفس الجودة. كما أنه يساعد في التأكد من أن جميع الأعمال تتم وفقًا للمواصفات ولديه فرصة ضئيلة جدًا للعيوب، حيث يمكن للمachine العمل على عدة حبيبات بلاستيكية في وقت واحد. هذا الأمر أصبح أكثر أهمية من أي وقت مضى للعملاء الذين يحتاجون إلى منتج موثوق به يعمل بشكل صحيح.

ماكينة تشكيل البلاستيك بالحقن. اختراع ماكينة تشكيل البلاستيك بالحقن قد غير تمامًا كيفية صنع المنتجات في جميع أنحاء العالم. غاري غازارخ، 29 أبريل 2020. الاستخدام من قِبل قطاع السيارات قد أظهر نتائج كبيرة. أوقات إنجاز أسرع وتحكم معياري في الجودة. هذا يسمح للشركات بإنتاج كميات أكبر من المنتجات ذات الجودة العالية في وقت أقل. كما يتيح للشركات الابتكار في منتجات جديدة ويضمن لها أن تبقى تنافسية في السوق. ماكينة التشكيل بالحقن ضرورية للمصنعين الذين يرغبون في تحسين قدراتهم الإنتاجية لأنها تتيح لهم العمل على منتجات ذات أشكال وأشكال معقدة متنوعة. يمكن للشركات الابتكار بشكل أفضل والتواصل مع عملائها بأفكار منتجات جديدة ومثيرة قبل المنافسين.

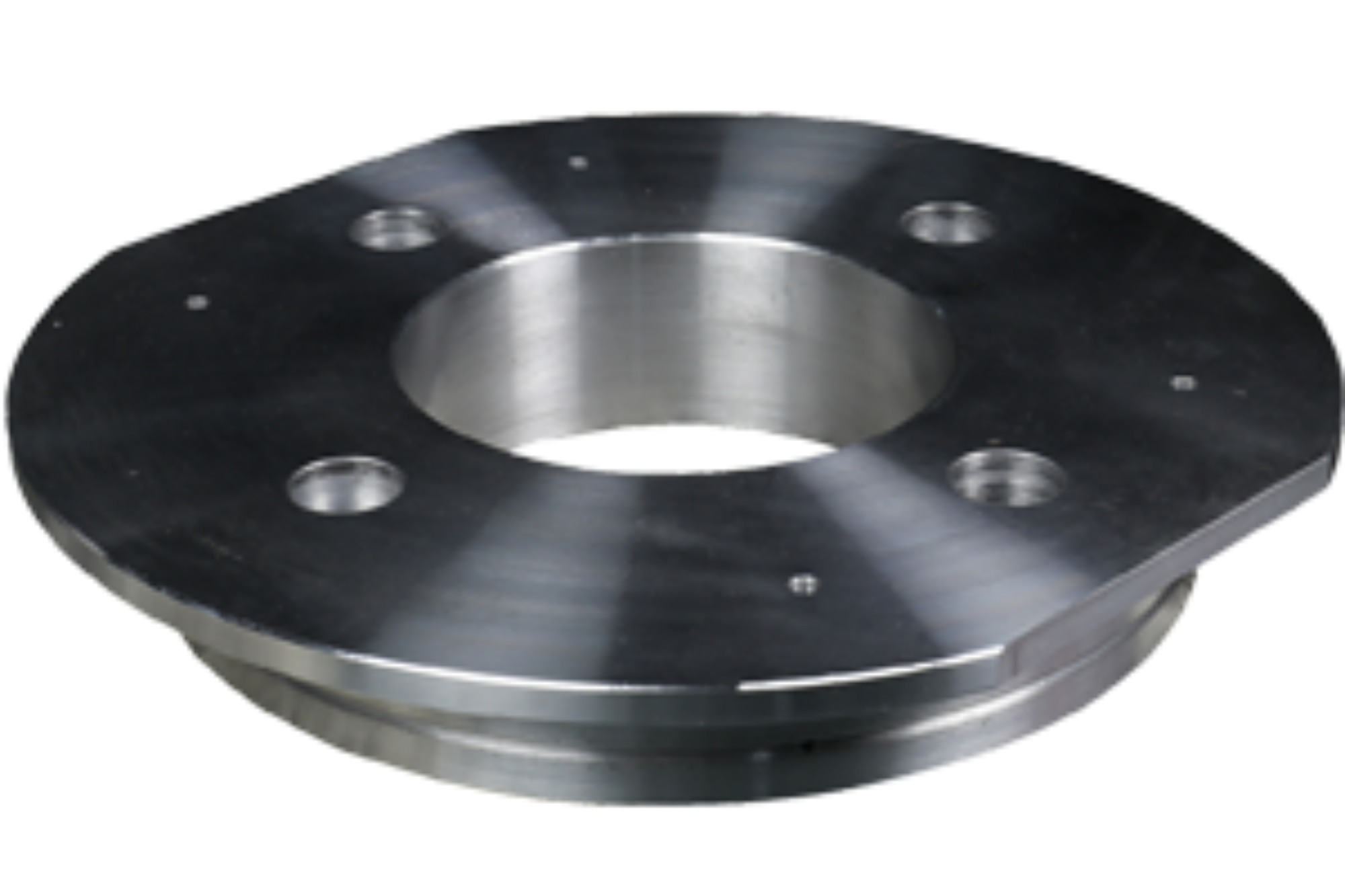

تم تصميم ضواغط صب الحقن والخدمات التي تقدّمها شركة بينغتشنغ لمساعدة العملاء على تحقيق أهدافهم التجارية. ونحن نركّز على توسيع إمكانات إنتاجكم وزيادة عمره الافتراضي. وتُعدّ شركة بينغتشنغ منتجًا موثوقًا به تبحثون عنه. كما أننا مورِّدون يوفرون فرصًا.

بينغتشنغ هي شركة تقدم خدمات شاملة وتُصنّع آلات حقن البلاستيك. وشحن منتجاتنا ليس سوى بداية شراكتنا معكم. وخدماتنا للعملاء تهدف إلى ضمان رضاكم التام. ولقد قدّمنا خدمات التصنيع لأكثر من 20 عامًا، وبنينا علاقات تعاون وثيقة مع شركات يابانية معروفة عالميًّا. ويستند التزام شركة بينغتشنغ بالأسعار الصادقة إلى خبرتها العميقة الممتدة على مدى عقود في هذا القطاع، وفهمها العميق لهذا المجال. فبمجرد استلامنا طلب اقتباس، نقوم بتحليل الرسومات باستخدام برامج متخصصة، ونقدّم أفضل الحلول بتكلفة معقولة.

وتضم شركة بينغتشنغ حاليًّا آلات حقن بلاستيكية و50 موظفًا فنيًّا مهرة جدًّا، ملتزمين بتقديم أعلى مستويات الجودة. وتُ calibrated أجهزة القياس الخاصة بشركة ميتسوتويو وأجهزة قياس الإحداثيات (CMM) بشكل دوري. كما أن نظام المراجعة المزدوجة يضمن موثوقية ودقة الجودة. وبإمكاننا تتبع جميع المكونات الأساسية وضبط عمليات التشغيل والتركيب بدقة.

تستند التزامات بينغتشنغ بالأسعار الصادقة إلى سنوات من الخبرة في المجال والمعرفة. وبعد استلام طلب الاقتباس، نقوم بمراجعة الرسومات ومحاكاة ضغط صب الحقن في أسرع وقت ممكن، ونقدّم أفضل حلٍّ من حيث التكلفة بالنسبة لك.