Low-pressure hydraulic accumulators are important positions in many other arcs hydraulic system, and it has the absolute advantage that can not only be used to boost performance but also improve safety. With low pressure hydraulic accumulators getting more popular by the day thanks to various advantages linked with them, technological progress is only going to carry forward this popularity for some time now. The most adaptable of these devices are meant to lock fluid in or consolidate it gradually (as is done with low-pressure hydraulic liquid) over inconceivable stretches, fitting for everything from a simple pump and cylinder-based power unit all the way up tp complex machines.

One of the major benefits, when using low-pressure hydraulic accumulators is that turnaround times gets a lot better with heightened accuracy. These same energy-efficient miles also save on battery life, further reducing operational costs.(Image: EnerFly) In addition, the maintenance expense of low pressure hydraulic accumulators is much less expensive than traditional systems that makes them a best selection for various markets.

Low Pressure Hydraulic Accumulators are used in various industries like construction and agricultural equipment on mobile hydraulic systems, as well as control systems for processes such chemicals or oil & gas. Its flexibility and reliability make them essential in guaranteeing the optimal functionality of machines, tools, or systems.

Selecting the right low-pressure hydraulic accumulator for particular application can be overwhelming but essential to ensure best performance of a system. A number of variables that must be taken into account when making a selection, these include the required fluid volume, pressure and flow rate as well as environmental considerations & system constraints

First up is to establish what the system fluid volume, pressure or flow rate requirements are. Then the choice of which style accumulator to use bladder, diaphragm or piston will depend more on application specific requirements. This variety provides the opportunity to choose a path that corresponds with your own individual life and career style, but also requires an informed decision process.

The second more important things to consider when you select mini hydraulic accumulator is what kind of work or job that need can be fully in the working place. Temperature, humidity, vibration and shock are all factors that can have an adverse affect on how the accumulator meets its design parameters throughout its life. Hence, a choice of knowing how it can work under these demanding condition will go long. Another thing to consider is the fluid used in the system, as you would need an accumulator that can withstand this specific type of fluid.

To take care of the low-pressure hydraulic accumulators they need to be regularly maintained. Taking care of the behaviour and using some tips/tricks will ensure better life for your accumulator (the dive computer) less wear:

Check the pressure levels frequently to avoid over/under-pressurizing that can harm your vaporizers internals.

Check all the hydraulic fluid levels regularly and look for signs of leakage or contamination as these can lead to performance interference.

Examine the accumulator for wear and tear, bending or indentations that can indicate they are damaged and need to be replaced.

Follow the manufacturer recommended maintenance procedure and replace parts/fluids that are approved by your cars maker in order to keep the accumulators working as efficient.

The principle of operation for low-pressure hydraulic accumulators falls under the tenets of fluid mechanics, specifically Bernoulli`s equation and Pascal's law. The accumulator holds the hydraulic fluid for use by means of on demand dispensing, providing beneficial effect toward system stability and performance. Now before discussing various low-pressure hydraulic accumulators solutions, it is necessary to understand this principle so that you appreciate how essential they are for your standard hydraulic system efficiency.

The Bernoulli principle explains that fluids flow faster at lower pressures and slower under higher pressure conditions. The principle is crucial for fluid distribution-you want the fluid to move in and out of an accumulator with ease. Conversely, Pascal principle suggests that pressure is constant throughout a liquid and since the accumulator operates containing fluid, it means its internal pressure equals to the hydraulic system. This principle, applies to the low-pressure hydraulic accumulators that helps sustain system stability and performance.

There are countless varieties of low-pressure hydraulic accumulators that suit the different needs across all manufacturers, OEMS and suppliers. Examples of major players operating in this industry are Parker Hannifin Corporation, Hydac International, Bosch Rexroth AG, Racine Federated Inc., Womack Machine Supply Company. Meanwhile, these firms offer a wide range of low-pressure hydraulic accumulators that include piston, bladder and diaphragm styles. In addition, they offer professional advice and technical assistance to help customers choose the appropriate accumulator for their individual needs.

Low Pressure hydraulic accumulators offer a number of advantages, including improved system response time, lower energy use and cost savings as shown in figures n-4 - 6. It is critical to properly select and maintain these accumulators to provide years of trouble free and performance optimized life. Together, we can investigate deeper into the scientific principles of low-pressure hydraulic accumulators and identify trusted manufacturers to keep hydraulics at their finest.

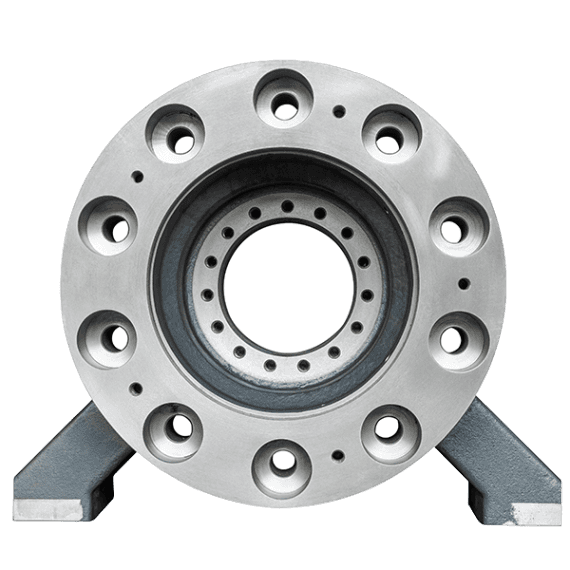

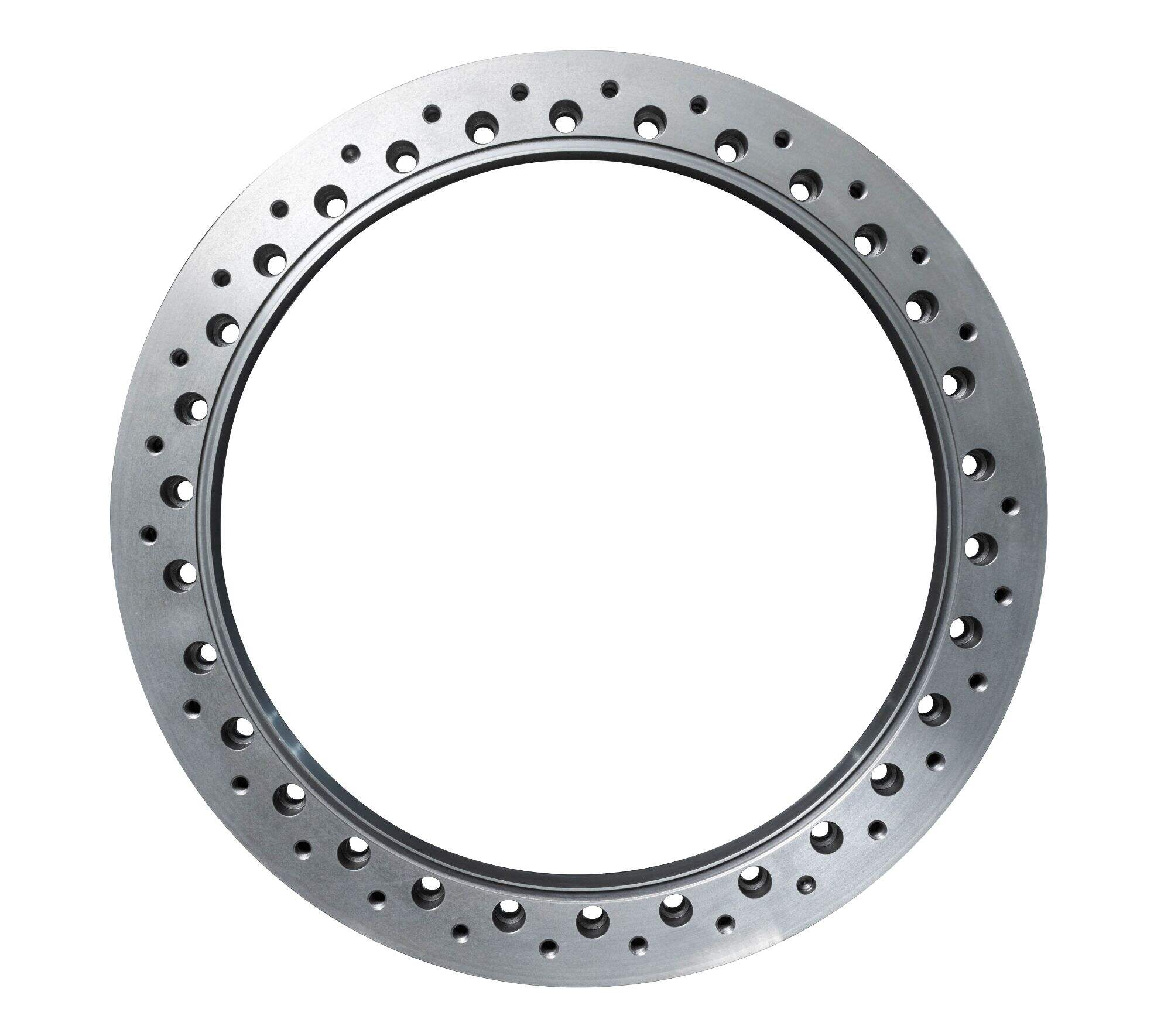

Pingcheng is committed to helping customers realize their business goals through our supply chain and low pressure hydraulic accumulator. We concentrate on helping you increase the lifespan and potential value of your products. PingCheng can be the reliable manufacturer that you need. We are a trustworthy partner that can provide opportunities.

Pingcheng now low pressure hydraulic accumulator and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.

Pingcheng is a low pressure hydraulic accumulator and lifecycle partners. The supply of the products is just the beginning of our partnerships. Our customer service is about ensuring your satisfactions. We have been offering the machining services and establishing a close partnerships with well-known industry Japanese companies for more than 20 years. Based on decades of experiences and knowledge of this field, Pingcheng is dedicated to offering our customers an honest prices. We examine the drawing with an advanced software program and then provide the best solution at a reasonable prices once we have received the requests for quotation.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We low pressure hydraulic accumulator, recreate it in specialized software, and then provide the most competitive price.