Injection molding is a process that many people use to create various items, including toys and combs as well an automotive parts. For this, they require a special type of machine that is called as injection molding machine. The clamping unit is an indispensable component of the machine. Here is a more detailed examination of how this piece operates and why it matters.

The clamping unit is responsible for keeping the mold closed and in position as the plastic flows into it. Now, what exactly is a mold? The mold is analogous to a giant empty building made in the shape of your toy, comb or car part. Step one involves getting the plastic super hot so that it melts. Liquid plastic is then shot into the mold after it melts. After the plastic cools, it forms a solid object in that shape. This translates to, the mold is indispensable in producing the end product.

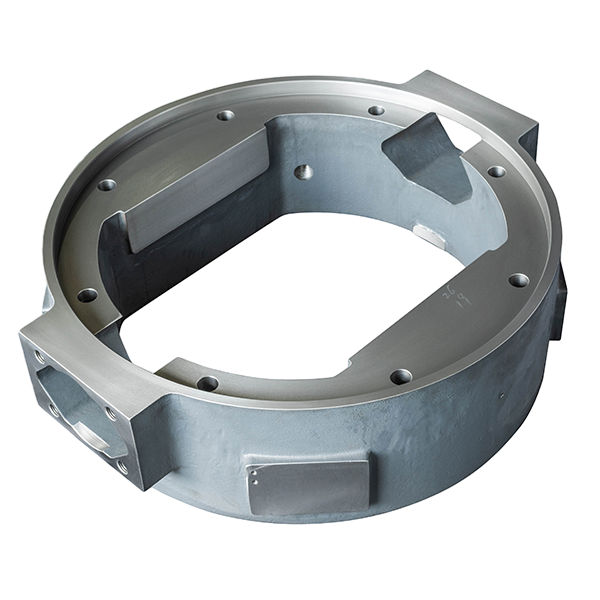

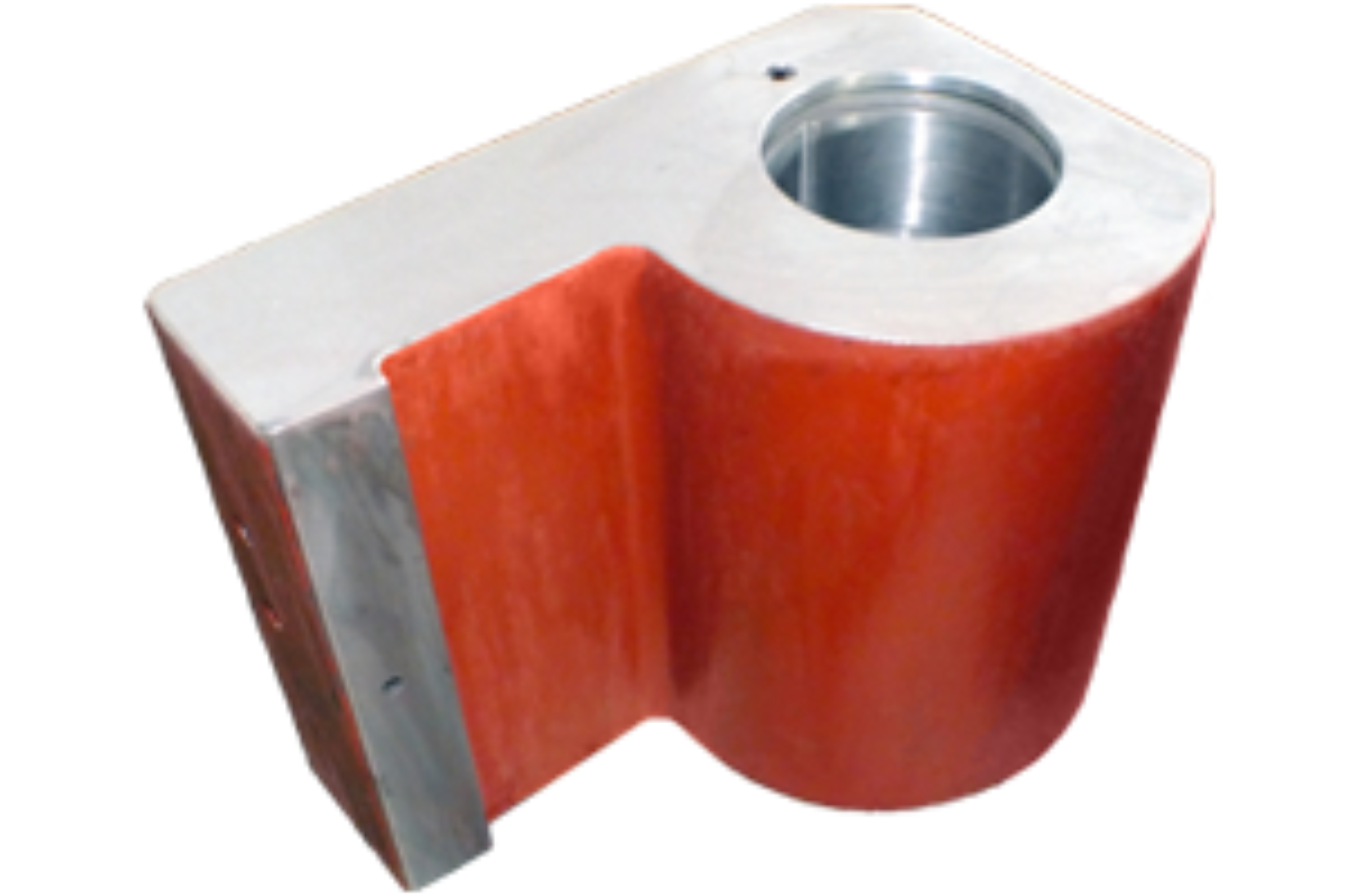

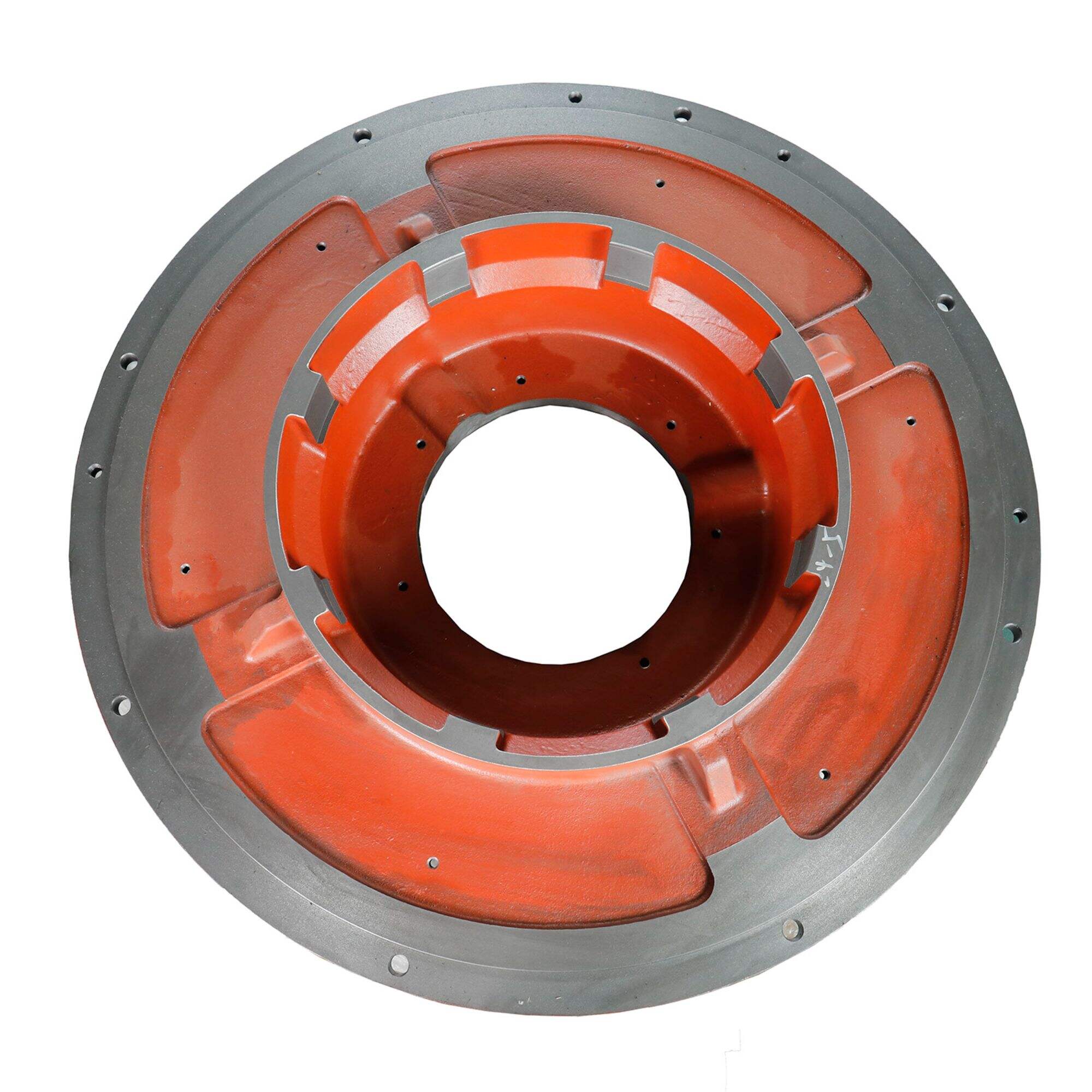

Two plates make up the clamping unit, one for each of top and bottom plate. Both the plates help each other to keep the mold tight. They must point very well together to ensure the melted plastic does not slide out. If the plastic leaks then difficult to manage product can not make. We refer to it as the clamp unit, and this clamps around the form where we hold everything in place.

So, how does the clamping unit work in real? A toggle is a special device used by the clamping unit to tightly clamp the mold. Composition of this toggle there are several brewers and developers can move inside so that the legs spider-paced. When the clamping unit wants to close, these bars and links whack against each other. The squeezing of the mold is done in this action, now both plates come together and ensure that the die does not move.

The clamping unit should be kept clean and lubricated to ensure that your injection molding machine is running at top efficiency. Meaning it clean, there was no dust or any debris that could be a problem. Oil also plays an important role by acting as a lubricant for the sliding of plates. This can cause the plates to bind and slow production, as well as make it difficult for you to use your machine.

There may be malfunctions found during the clamping process of injection molding machines. Flash (Common Issue) Another common problem is Flash. Flash is a little bit of plastic that comes out the edge where two halfs come together, likely because the plates were not tight. This leaves a small extra thin piece of plastic around the edges, making it hard to peel off later on.

In the world of injection molding, there are endless possibilities for new ideas and enhancements. A new innovation in this area could be something called electric clamping. So instead of pneumatic pressure, air to close the clamping unit it uses electricity rather than hydrolics which is use liquid for that. The aim is to make electric clamping even faster and energy efficient than at present.

Pingcheng is a full-service and injection molding clamping unit. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Based on injection molding clamping unit and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Pingcheng today has more than 20 manufacturing facilities and more than injection molding clamping unit. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and injection molding clamping unit. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.