لوحة الإخراج هي أداة قيمة تساعد في واحدة من العمليات الخاصة التي نسميها تشكيل بالحقن. إنها عملية شائعة جدًا لصنع العديد من المنتجات، ولا تكون أي منها معدنية بل مصنوعة من البلاستيك. تساعد لوحة الإخراج في دفع المنتج النهائي من القالب، أي شكله. سيناقش هذا المقال ما هي لوحة الإخراج وكيف تعمل. سنتحدث أيضًا عن الأسباب التي تجعل لوحة الإخراج مفيدة للمصنعين ونتطرق إلى بعض المشكلات الشائعة في الإخراج. وأخيرًا، سنتحدث عن لوحات الإخراج وكيف يمكن أن تكون حاسمة لنجاح مشروع معين على آخر؛ لضمان اتباع أساليب جيدة في تصميمها.

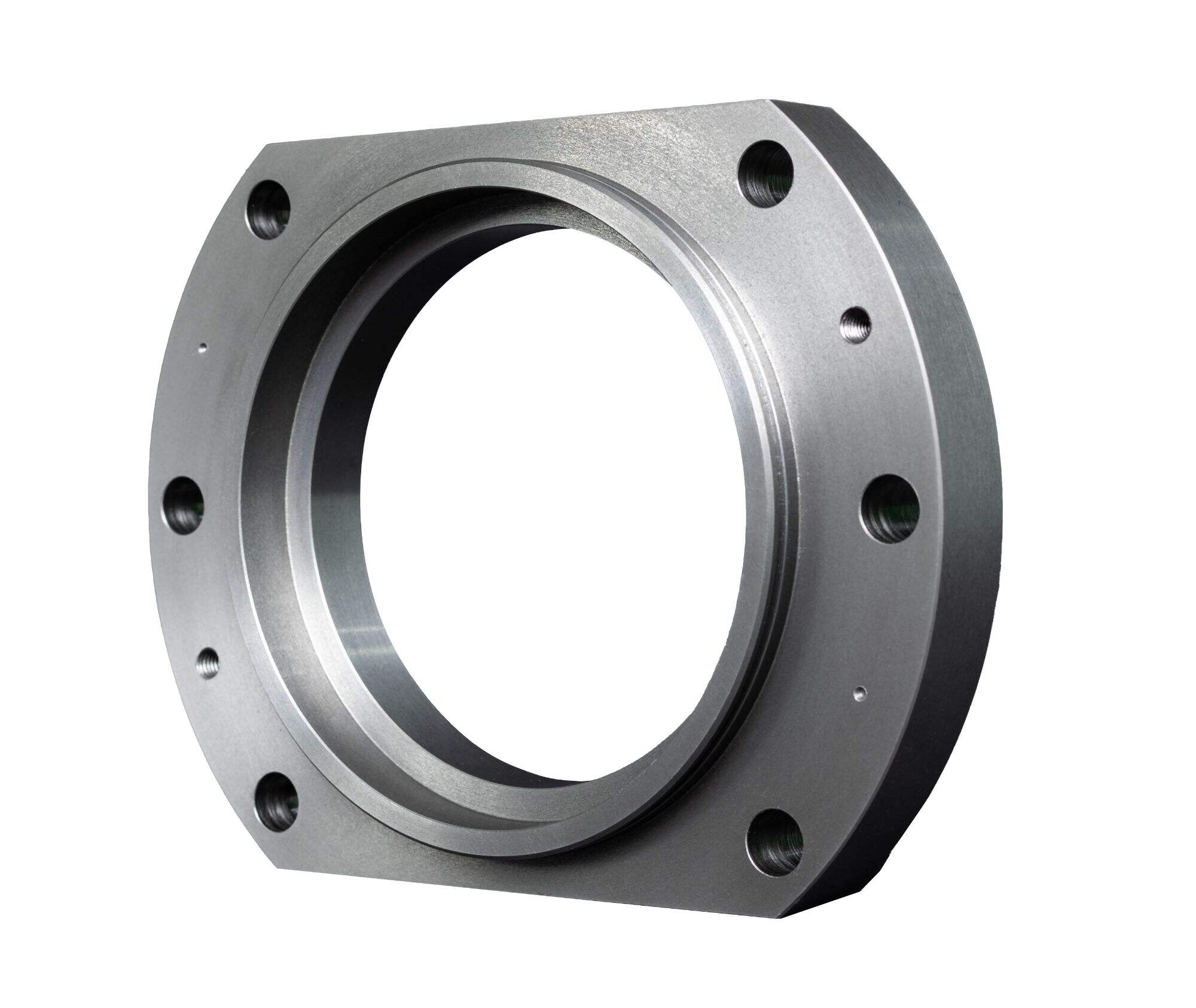

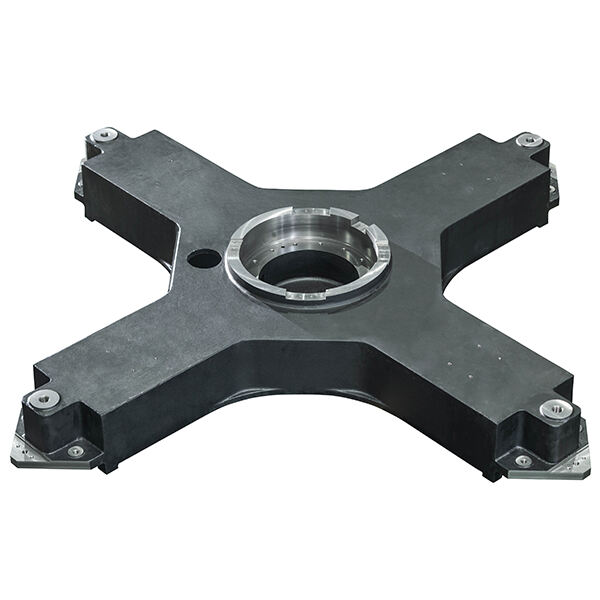

لوحة الإخراج هي قطعة معدنية مسطحة تقع بين القالب والماكينة التي تنتج المنتجات. عند حقن البلاستيك في القالب لتشكيل شكل معين، تبقى لوحة الإخراج في مكانها لتوفير الوقت اللازم لتبريد وتجفيف البلاستيك بشكل صحيح. التبريد مهم جدًا لأنه يسمح للبلاستيك بالتكيف بسهولة وفقًا لشكل القالب المحدد. بعد أن يبرد ويتماسك البلاستيك إلى درجة لا يمكن إعادة تشكيله فيها، تتحرك لوحة الإخراج للأعلى مما يدفع المنتج خارجًا بواسطة 'قضيب الدفع'. من المهم أن يتم تصنيع المنتج بطريقة فعالة بعد هذه العملية وسيتم فصله عن القالب (وهذا الجزء من العملية يُسمى الإخراج).

في عملية تشكيل بالحقن، تمتلك لوحة الإخراج العديد من المزايا. الفائدة الرئيسية هي أنها توفر لك الوقت. بدون لوحة الإخراج، سيتعين على شخص ما إزالة القطعة النهائية يدويًا من القالب. سيكون هذا عملًا شاقًا ومكلفًا من حيث الوقت لأن إنتاج كمية كبيرة من المنتجات في وقت قصير أمر صعب. استخدام لوحة الإخراج يمنع أيضًا احتجاز المنتج داخل القالب. يمكن أن تصبح الأشياء محشورة بشدة، خاصة إذا كانت عند درجة حرارة مرتفعة، بحيث يصبح من الصعب إزالتها دون تلف المنتج، وهناك هدر في الوقت مع زيادة التكلفة/استخدام الطاقة للمصنع.

إذا تم استخدامه بشكل غير صحيح، يمكن أن يسبب لوحة الإخراج بعض المشاكل. ومن دون أن نذكر أنه قد تكون قد بذلت الكثير من الجهد والوقت للحصول على المنتج النهائي مثاليًا فقط ليكون غير قادر على الخروج من القالب. هناك العديد من الأسباب التي قد تؤدي إلى ذلك، فقد تكون لوحة الإخراج مُصممة بشكل غير صحيح أو أن تسلسل عملية الإخراج لم يتم ضبطه بالشكل المناسب. لذلك، من الضروري للغاية أن يتم تصميم لوحة الإخراج بشكل صحيح وضبط تسلسل عملية الإخراج بشكل سليم. مشكلة أخرى قد تحدث هي أن المنتج نفسه قد يتشوه ويأخذ شكلًا مختلفًا عند إخراجه. يحدث هذا بسبب تبريد غير صحيح للمنتج و/أو ضغط إخراج غير مناسب أثناء التشكيل. لكن من الضروري التحقق من هذه المشكلة وتركيب نظام تبريد مستقر أيضًا، حتى يتم الحفاظ على ضغط الإخراج متوافقًا مع العملية الخاصة بك طوال عملية التشكيل.

هناك بعض الأمور التي يجب مراعاتها أثناء اختيار لوحة الإخراج لمشروعك. يظهر أن حجم المنتج هو أحد العوامل الأكثر أهمية. يجب أن تكون لوحة الإخراج بالحجم المناسب لشكلك. إذا كانت اللوحة إما صغيرة جدًا أو كبيرة جدًا، فسيكون هناك مشكلة لأي دارة إخراج. عامل آخر لا يمكن تجاهله هو المادة المصنوع منها لوحة الإخراج. يحدث تغيير في الضغط عندما يتم الإخراج، لذلك من الحكمة اختيار مادة قوية يمكنها تحمل كل هذه الضغوط. وأخيرًا تصميم لوحة الإخراج، هذا مهم جدًا. استخدام لوحة الإخراج أو عدم استخدامها غالبًا يكون الفرق بين منتج جيد ومشاكل التشوه والانحناء معه.

الموقع الشعاعي للقطر المقطوع من حيث لوحة الإخراج له تأثير على جودة المنتج النهائي. استخدام لوحة إخراج مصنوعة بشكل جيد يمكن أن يساعدك في منع العديد من المشكلات التي تحدث بسبب التواء أو التشوه. كما أنها تضمن طرد المنتج بسلاسة وسرعة، وهو أمر مهم لإنتاجية العملية. تصميم لوحة الإخراج يعتمد بشكل أساسي على حجم وشكل المنتجات المصنوعة عند اختيار المكونات لتشكيلها، وكذلك اختيار المادة. أخذ جميع هذه النقاط بعين الاعتبار سيسمح لك بتطوير لوحة إخراج تناسب مشروعك الخاص، والتي تؤدي إلى تحسين جودة الإنتاج.

وبناءً على عقود من الخبرة في مجال لوحات القذف، تلتزم شركة بينغتشنغ بتقديم أسعار عادلة لعملائها. فنحن ندرس الرسومات الفنية، ثم نصمّم النموذج باستخدام برامج متخصصة، وبعد ذلك نقدّم لك أدنى سعر ممكن.

تضم شركة بينغتشنغ حاليًا لوحة طرد و50 موظفًا فنيًا من ذوي المهارات العالية، وتسعى جاهدة لتقديم منتجات عالية الجودة. بعد ذلك، يتم فحص المنتجات بواسطة أجهزة قياس ميتسوتويو وجهاز قياس إحداثيات ثلاثي الأبعاد (CMM) تتم معايرته دوريًا. يضمن الفحص المزدوج جودة موثوقة ودقيقة. كما يتم التحكم في عمليات تصنيع وتجميع الأجزاء المهمة وتتبعها.

تم تصميم سلسلة التوريد والخدمات التي تقدّمها شركة بينغتشنغ لمساعدة العملاء على تحقيق أهدافهم التجارية. ونُوفّر ألواح القذف بالإضافة إلى تعظيم القيمة والعمر التشغيلي لمعدات التصنيع الخاصة بكم. وتُعَدّ شركة بينغتشنغ مصنّعًا موثوقًا به تبحثون عنه. كما أننا مورّدون يقدمون مجموعة متنوعة من الخيارات.

تركّز خدمة العملاء لدينا على رضاكم. ولقد قدّمنا خدمات التشغيل الآلي وألواح القذف للشركات اليابانية المرموقة في مجال الصناعة لأكثر من ٢٠ عامًا. واستنادًا إلى خبرتنا الطويلة ومعرفتنا العميقة بالصناعة، تلتزم شركة بينغتشنغ بتقديم أسعار صادقة لعملائها. ونقوم بتقييم الرسومات باستخدام برامج متخصصة، ونقدّم أفضل الحلول بأقل التكاليف المعقولة بمجرد استلام طلبات الاقتباس.