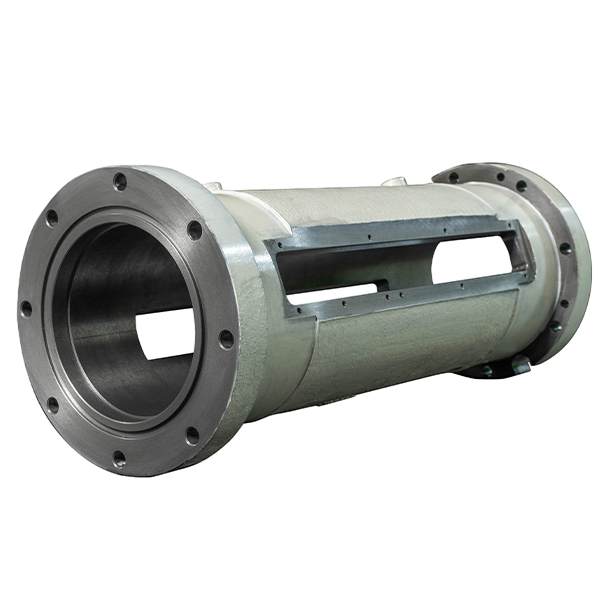

Clamp injection molding is a widely used process for producing plastic parts. It works by using a machine to melt plastic and then inject it into a mold that matches the part you want to create. Once the plastic is cooled and set, the part is removed from the mold. Why Motor Flange Pingcheng Our company is professional manufacturers and suppliers of these productions.

High Precision Clamp Injection MoldingPingcheng technology is suited for industries that need the production of detailed and precise parts. Our equipment is state-of-the-art, so you can count on the highest quality and precision every time. Whether it be automobile parts, or medical instruments, our molding process creates parts that will meet and exceed your expectations for fit and function rights.

In industrial applications, resistence is key! In Pingcheng, our clamp injection molding techniques are especially geared towards manufacturing parts that are both strong and durable. We of materials that can be prolong working life in different environment. This is what makes our products highly durable for the toughest of industrial environments.

If you are a business needing to purchase large clamping injection molding machines, China's Pingcheng is affordable for you. We even provide wholesale pricing on large orders, so that wholesale buyers can access high-quality parts at even lower prices. Our streamlined production processes also enable us to quickly manage and fulfill large orders, while still delivering the high quality of product you have come to love.

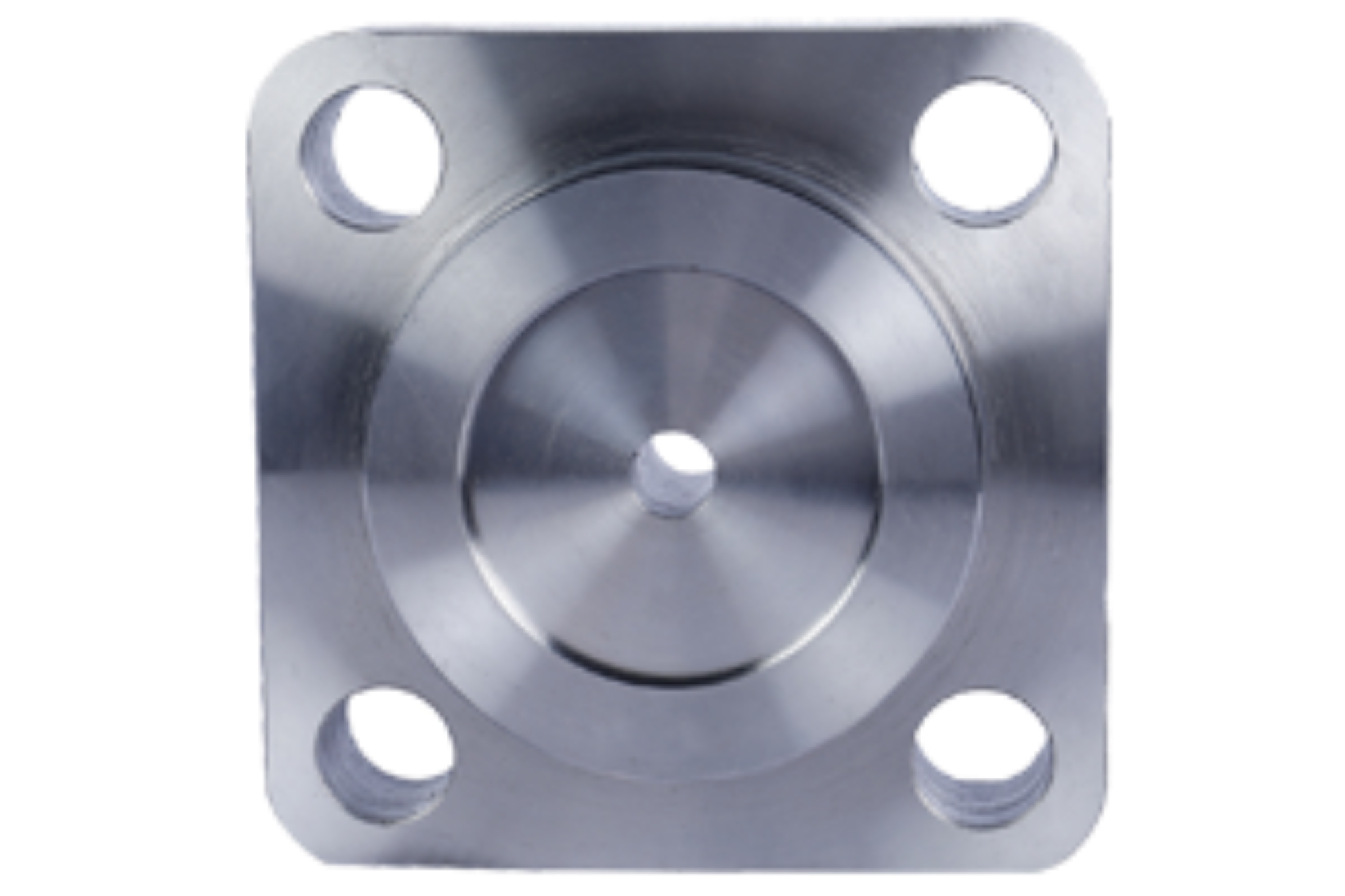

We realize that every project has different requirements, and at Pingcheng, we get it. It’s for this reason that we provide custom clamp injection molding services. Our staff collaborates closely with the clients to get to know their needs and adjust our process accordingly. Whether you require a custom material or custom design we can assist you in making your project successful.

Pingcheng is committed to helping customers achieves their business goals through our clamp injection molding and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate clamp injection molding as soon as we can, and provide the best solution for your cost.

Pingcheng is a clamp injection molding and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng is now clamp injection molding and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.