If you want to have the proper clamp lock mould for your project, then Pingcheng has all you need in terms of quality molds. With outhard wholesale selection, there's no shortage of options for you to choose from no matter if you're working at a smaller or larger site. With years of experience of industrial manufacturing, Pingcheng is dedicated to offering well-designed and high quality product of great value. We are committed to assisting you get the ideal clamp lock mold solution for your particular application from design to manufacture to service.

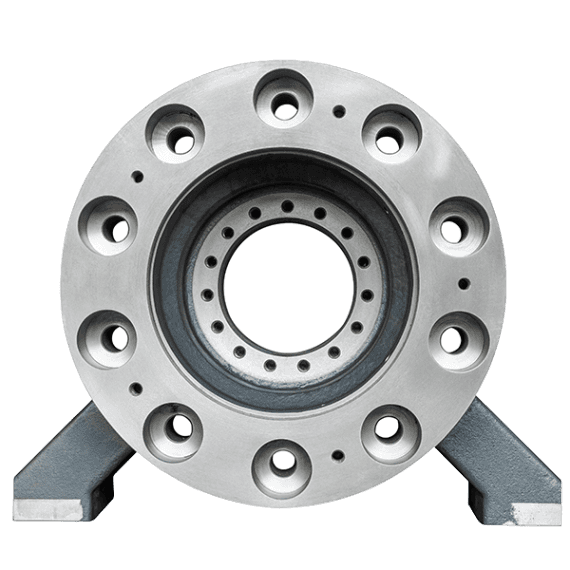

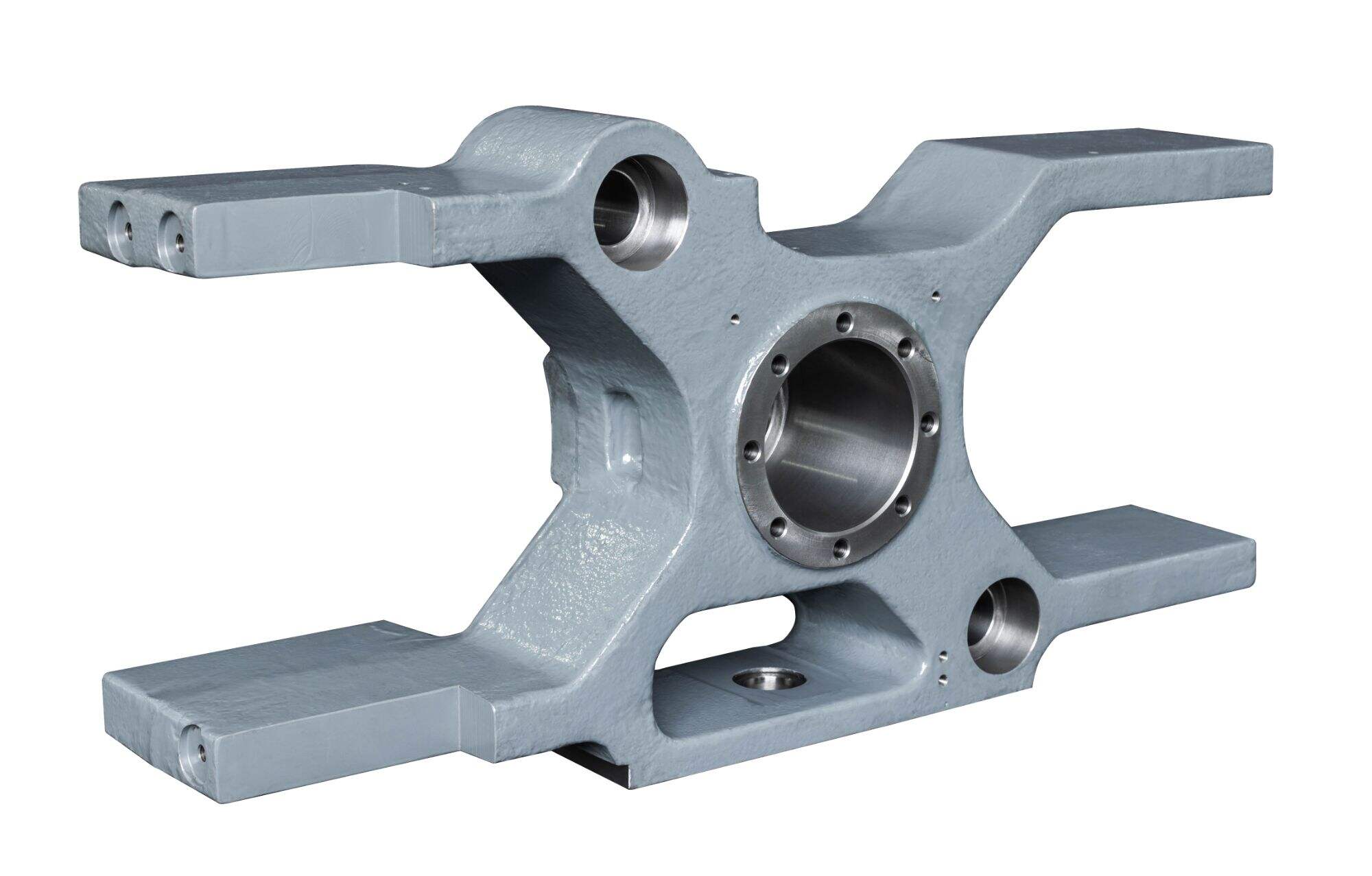

Pingcheng provides the most popular clamp lock mold for wholesale and is widely known by people of different requirement. We take pride in our quality and the performance of our products, and offer something to everyone from boot camp enthusiast to surf pro. Whether you’re looking for off the shelf or custom, we have a mold that will fit your project! Every detail is carefully thought in order to ensure the excellent performance of Pingcheng industrial manufacturing, such as shell cavity size, position and number of screw holes.

There are a number of things to take into consideration when choosing the clamp lock mold that will work best for your joint project. First, consider the size and details of the mold that your project demands. It depends on the material applied and what you are using them for. Consider also, how accurate and detailed you will want your finished forms to be so that you select a mold that gives you those results. Through thoughtful evaluation of your project requirements and these factors, you will be well-poised to make the best selection for a clamp lock mold from Pingcheng for your upcoming industrial manufacturing project.

There are common problems that will occur in the clip lock mold factory production. One of the primary issues is mold misalignment, which results in defective products. To prevent this problem from occuring, the mold allignment needs to be periodically checked and readjusted as required. Another problem that can potentially develop is mold degradation that will, in turn, lead to the degradation of products. To avoid that, the mold should be correctly maintained and cleaned after every usage. Poor clamping force can also lead to uncontrolled flash or low fill throughout the mold cavity. To prevent such a situation, be certain the clamp lock mold is tightly fixed before beginning production.

MOLD PART DESCRIPTION Clamp lock molds are an important part of the manufacturing process as they ensure the die halves remain fastened together during injection molding. This is to prevent any poor-quality defective of products. Without clamp lock molds there’s always the possibility of mold misalignment—meaning expensive repairs and delayed production. Furthermore, clamp lock molds aid to increase efficiency of the manufacturing process due to a decrease of the risk of mold wear. Quality The quality of products is a crucial factor for manufacturers, who can achieve better quality and consistency of product with high-quality clamp lock moulds.

Our customer services is clamp lock mold. For over a decades we've offered services for machining and developed a close cooperations with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based on decades of experience and a deep understanding of this fields. When we receive a an inquiry for a quote, we review the drawings and simulations in our specialized software as soon as we can, and provides the most appropriate solution at an affordable prices.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They clamp lock mold. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

Pingcheng is clamp lock mold achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

With years in experience and a clamp lock mold, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.