There are several elements to consider when selecting the die clamping system: Only a few are listed here, but they depend on the kind of tool that will be used. Various dies demand different clamping system for the secure fit and work properly. For example, if you are working with a heavy, large capacity die, you may require a tougher clamping system that can bear the weight and pressure. If you have a smaller die, however, a lesser clamping system might do.

Along with what kind of die, and the size of operation you have, it is also wise to consider the price point that comes along with purchasing a clamper. It may be tempting to choose the least expensive option, but always remember; it’s all about quality when selecting die clamping systems. Disposable systems just don't have the same long-term performance, and investing in robust clamping can be a cost-saving measure even if it comes at an initially higher price point.

In general, if are looking for the right die clamping system to suit your wholesale needs high quality Pingcheng is a reputable name in the business partner to supply you with suitable products at great prices. Be confident that with Pingcheng, you will have a socket you trust and can rely on for your most critical applications to get to market faster and improve your bottom line.

There are several problems that can normally be encountered in production processes when using a die clamping system. Misalignment is among the most frequent issues where the die and the clamping system are not aligned. This is a source of irregular contact pressure application and may lead to products having defects. The only solution to this problem is that the setting of alignment in die clamping system must be checked and adjusted periodically.

Insufficient clamp force can cause the die to move during processing; that is another problem you may encounter. When there is any deviation from the right level this can cause not true cuts and and inturn lower productivity. To solve this issue, the clamping system requires calibration to clamp with a force that is appropriate for a particular application.

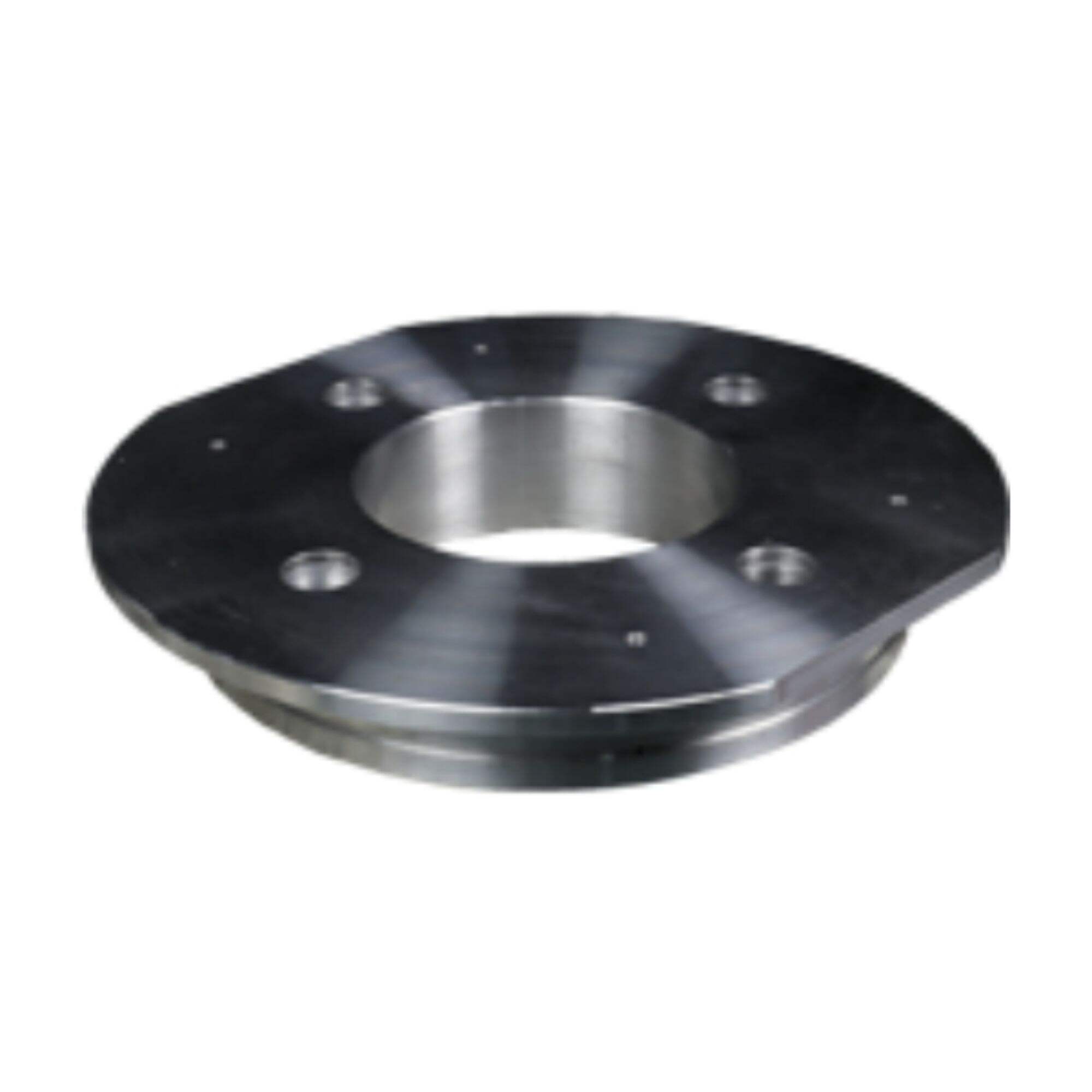

Die clamping devices must be provided when efficient production is to be ensured as they serve in fastening the die during operation. This helps to hold the die still and in place while cutting. Moreover, die clamping systems contribute to productivity by lowering the opportunity of mistakes, which can result in less downtime caused by misalignment or shifting of dies.

Several aspects must be considered when choosing a die clamping system for high volume or wholesale applications. A sturdy and rugged construction is a key feature to look for that will hold up to large volume work. Secondly, it is important to select a die clamping system that provides accurate parallelism and flexible clamping pressure for various die sizes and materials.

Pingcheng is now die clamping system and 50 highly skilled technical employees. They committed to providing highest quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. The machining and assembling of all keys components are easily traceable and controlled.

Pingcheng is a die clamping system and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we die clamping system, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.

Pingcheng is die clamping system achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.