Did you ever ask yourself how everything is made of plastic(plastic toys, cups and even car parts)? Vertical plastic injection molding machines - the magical witnesses of such things!

They work by melting a plastic resin into the mold. After the plastic has cooled and hardened; it conforms to the shape of this homosexual. The vertical construction of the machine guarantees evenly distribution of plastic into all mold cavities, providing an accurate and consistent moulding.

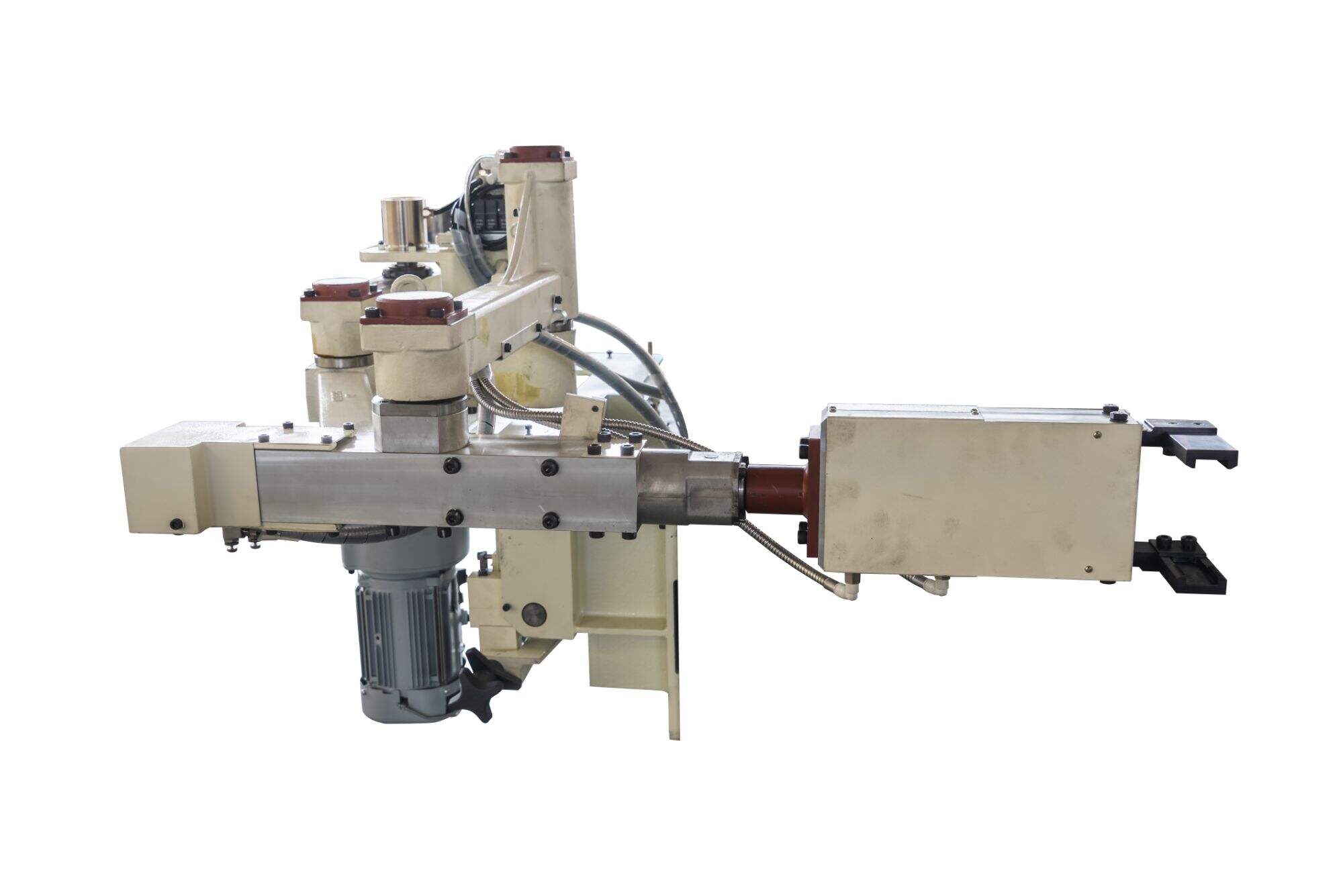

There are different types of vertical plastic injection moulding machines available with unique characteristics Single-shot machines make one plastic part at a time, and multi-shots create multiple parts per cycle. Shuttle machines also feature the ability to manufacture larger parts than other types.

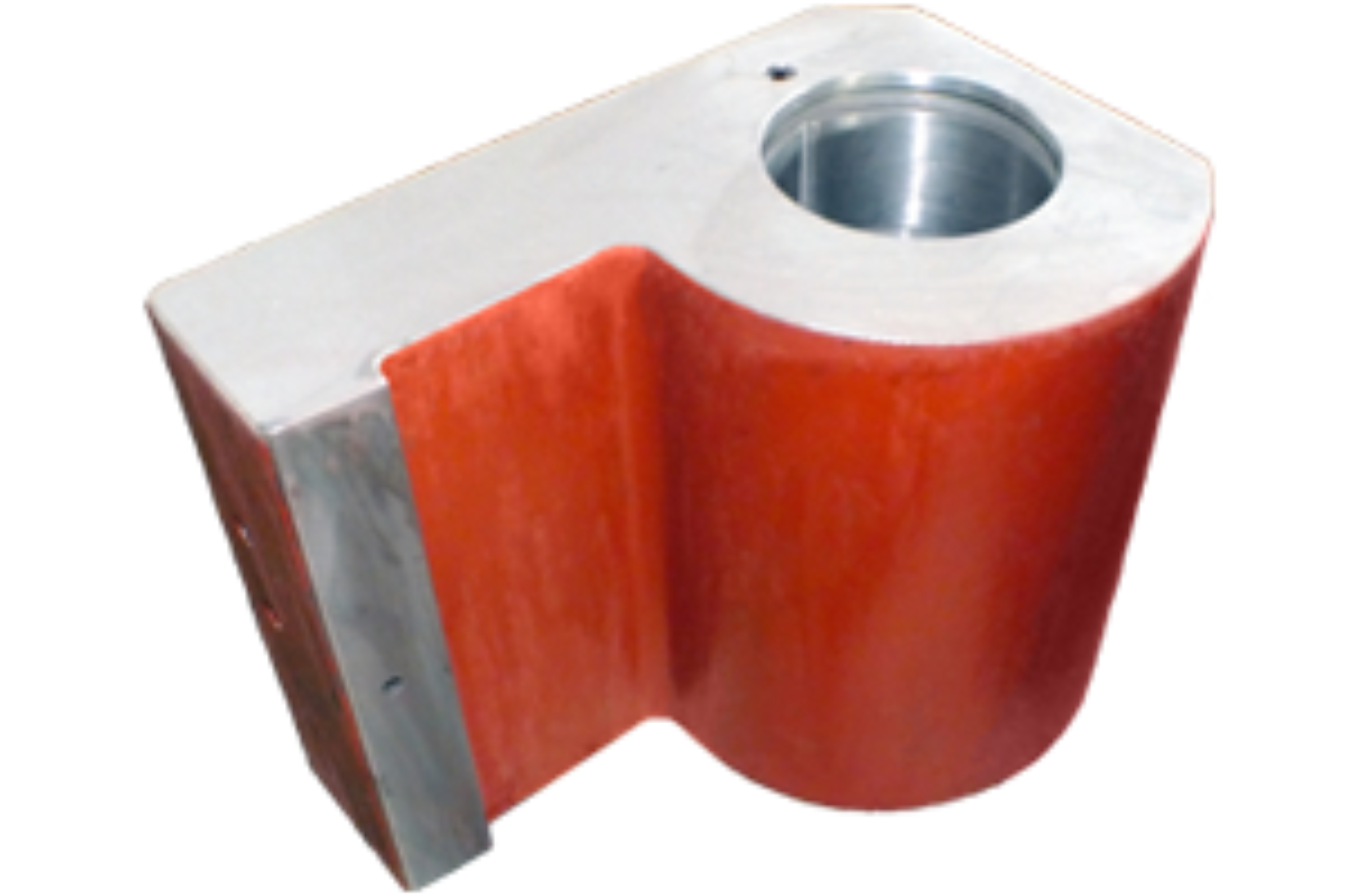

These machines work with hydraulic systems that essentially make them operate and a control panel to manage the machine. The plastic resin is kept in the hopper of the machine, and it has been melted along with injection through an injection unit into a mold.

It is therefore of great importance to choose the right vertical plastic injection moulding machine for your industry. Things to take into account are; the size, and complexity of parts you plan to make, along with long how many pieces your needing made. Other properties include clamping force, injection volume and speed of the machine which must be evaluated to guarantee that can handle for entering / processing a certain resin.

Operations of vertical plastic injection moulding machine should be optimized to have the best mold design. Inefficient productionMany often do not realise the importance of a good mould in ensuring smooth and efficient production. Routine upkeep like cleaning, oiling moving parts as well as changing worn out elements is also crucial. You must offer proper training to your operators so they know how the machine works and maintain a safe environment for them in order that everyone can work smoothly.

Vertical plastic injection moulding machines come with a good number of benefits like precision, versatility and energy efficiency; however they do have limitations. Although there are smaller than the horizontal injection molding machines, they can still be designed to manufacture big parts and also for large volume output. Vertical machines also have longer-cooling process, so they can affect the velocity of production.

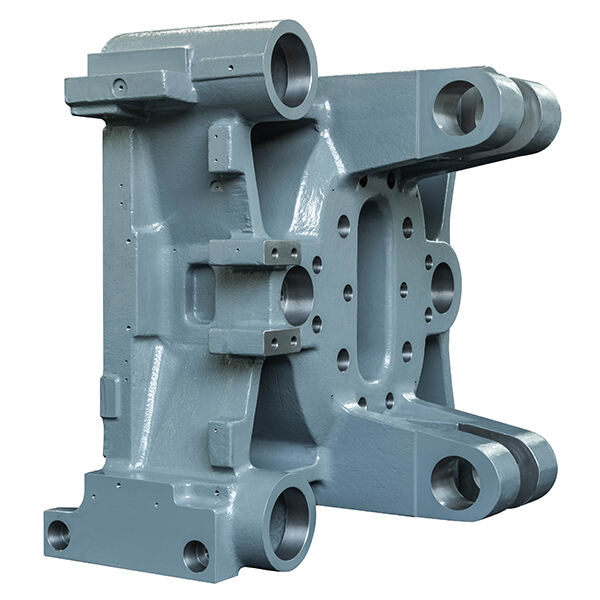

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our vertical plastic injection moulding machine. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

Based on vertical plastic injection moulding machine and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Pingcheng has at vertical plastic injection moulding machine and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and vertical plastic injection moulding machine. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.