Hank was an inventive little boy, and he had a talent for hacking his toys-He worked on the two-car garage next to half of one open to let in sunlight275-2017 outdoors with his dad who called him "my helper"1arge459 (a pet name that made Hank so proud)and they built these really cool devices together: They all functioned! In the afternoon, one of his friends who also has a dad stopped by at his home. He did not like showing off to his many machines in the factory. Hank was nearly giddy as he surveyed the machines, happily muttering to himself. But what never ceased to at least slightly intrigue him in particular were the devices holding apart whatever they concerned. The story was told to him by his father's friend dealing with clamping force units. Hank is curious by nature so he wanted to understand more about this intriguing topic.

Clamp-A clamping force unit, or clamp for short is a tool used to retain something together while the work processes on it. It is one of the most critical stages because, if this object moves, it can be harmful or anything that needs to be fixed will become difficult. Clamping force power is a measure that gives you idea of how much force could be applied by the clamps, and there are multiple variants for clamp components on securing different types of poses. These are separated into 2 types most commonly, adjustable clamps - which can be tightened or loosened to accommodate varying sizes of objects; and fixed-size crimpers intended merely for holding predetermined size items. That is to say, a clamping force unit would be quite versatile of which also means useful in many types of applications.

Or the items to be restored are small or delicate in nature? It is really required to equip a clamping force unit at that time, which will hold the product but does not damage as well would allow it from breaking. It is essential during the technique of precision machining. Precision machining is no different; a successful project can go off the rails with even one incorrect measurement. They are only the way by which these control clamping force remains demonstrating that final product is flat and nice looking. They micro-manage the heck out of everything so that all an employee has to do is show up and be his best self, and things will work just fine.

Clamping force units typically are dependents on different variables. How Hard is clamp pressed, weight of object and friction between clamp and object etc so these all can affect how efficient does unit works. So you must inspect and regulate these elements to ensure have a functional clamping force unit. A torque wrench is an extra tool that helps in adjusting the pressure on the clamp. This will let you determine what type of pressure is placed on your goal and adjust, as well as create a solution to that specific kind of resistance. Various clamps may be used to give more force into needed places simply by adjusting their position and changing the angles of applied pressure depending upon object size or shape, etc.

Through the techvolution, force of clamping units have become way more stronger and dependable. It is also available with some of the modern clamping force units these days which has other types of sensors installed for registering even a minor change as totolity. These sensors measure the sudden stop of a fall and react to hold together. This means that the handle remains at its place and does not move as you carry out your work. There are also the flange clamps being replaced by burlier, badder clamp materials. This is especially useful in trades where you hold heavy stuff over periods of time and things tend to get dangerous.

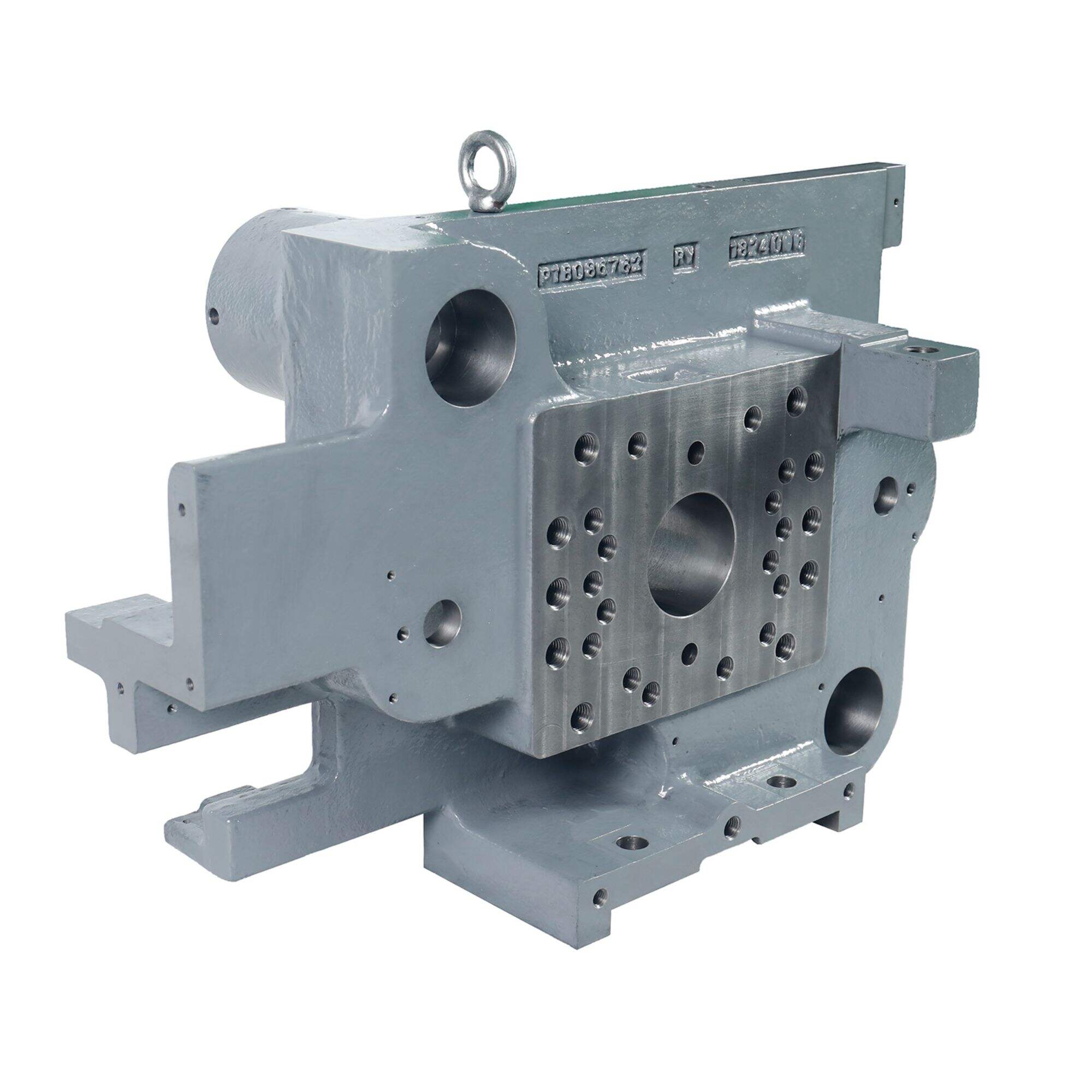

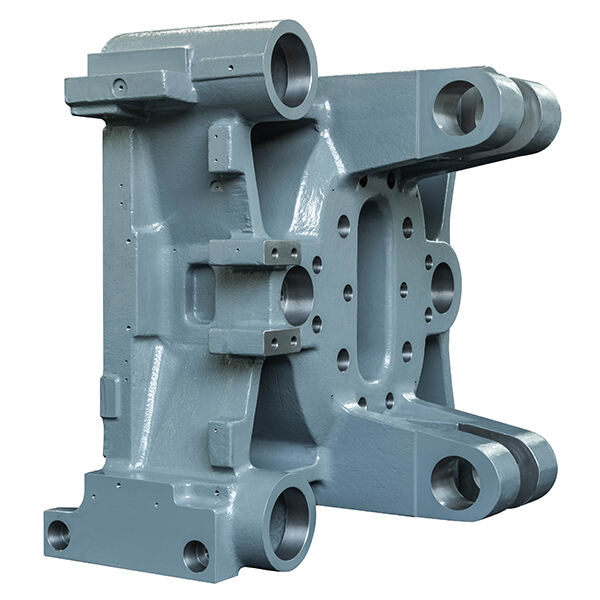

Pingcheng has now more than 20 manufacturing machines and clamping force unit with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a clamping force unit you've been searching for. We are a partner which delivers opportunities.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with clamping force unit for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.

With years in experience and a clamping force unit, Pingcheng is dedicated to providing customers with honest price. When we receive a the request for quote, we review the drawings and simulates using special software right away, and then provide the most effective solution with a fair price.