CNC die casting is a method of producing metal parts. Metals are melted and then poured to solidify the cast. As the hot metal cools, it becomes hard again and has molded itself accordingly. It is then allowed to cool down completely and next the mold is opened up, & metal part will be taken out of it with utmost care in opposition to any possible deformation. This technique is widely used by great amount of different industries like — Automotive (building cars), Aerospace(airplanes) and medical industry with health care & medicine.

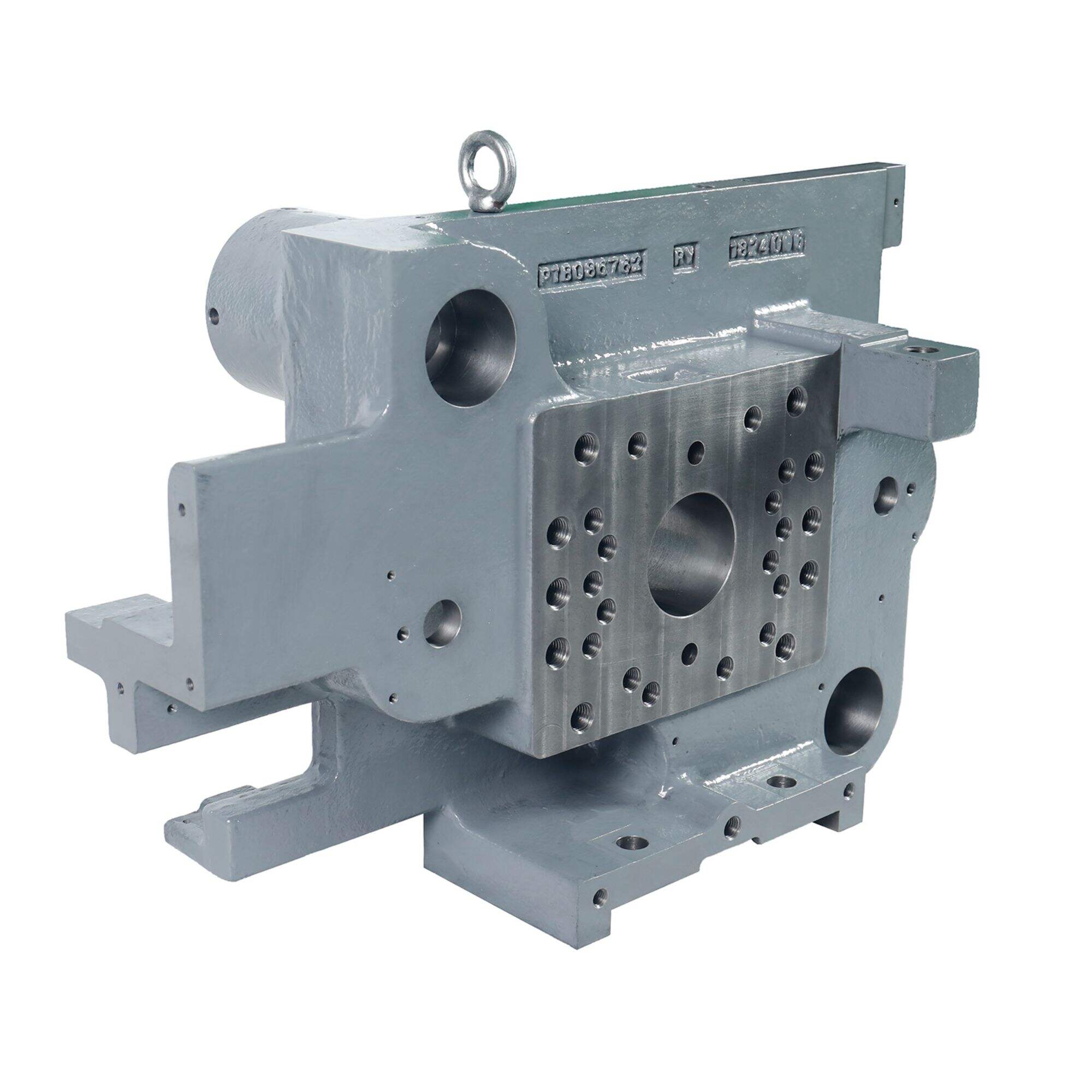

Creating objects by melting metal and putting it in a mold, CNC die casting is an exceptional process. It generally consists of heavy steel and contains a hollow cavity which is in the shape of an intended component. Thereafter, when the metal is melted to its hot condition so as it can be poured into a mold, this is done through closing the other part of sheave with a danger that resides inside.

The metal then cools and solidifies, matching the exact shape of the mold. This ensures that once it is fully cold, the mold will open and allow for easy removal of the metallic part. The whole process is greatly accelerated, that is why so many companies choose this method to do tonnes of parts simultaneously and efficiently.

One of the primary reasons to switch over from Traditional die casting to CNC Die Casting Machies is because it can produce complex parts in a more faster and efficient manner. Because CNC die casts come out of very precise molds, the parts made from them are also virtually perfect. Accuracy is crucial, particularly in industry where little errors spell trouble.

Yet another benefit of CNC die casting is it works with almost any material. These consist of aluminium, the most frequent, magnesium and beryllium as well as zinc which is not rusty. Besides, CNC die casting is also available for other materials such as plastics and ceramics. Because of this flexibility, the CNC die-casting could also be a widely broad technique excellent for many jobs in different industries.

CNC die casting can be done using a variety of materials, which all come with their specific advantages. Aluminum is one of the widely used materials for respiration disk. Its low weight, high strength and good resistance to common forms of corrosion makes aluminum a first-choice material for many applications. Lighter even than aluminum is magnesium, and it too has great strength.

First of all, like any other type of technique that requires some form for not-exactly-natural processing to be effective it is imperative that the moulds are made very exact. In other words, the parts coming out of molds made correctly will be correct. Checks to be conducted include, inspecting the parts as they are being ejected from molds making sure there is no defect or issues on it. This helps to guarantee that each component meets the high level of quality needed for various industrial applications.

Pingcheng today has more than 20 manufacturing facilities and more than cnc die casting. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and cnc die casting with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a cnc die casting you've been searching for. We are a partner which delivers opportunities.

Based on cnc die casting and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.